Introduction

What is Put-to-Light?

“Order breakdown” or “scan-sort” processes is a common warehouse process where orders are massively picked as a first step then sorted in a second step to fulfill each single customer’s needs. It is tremendously efficient with huge volumes, small orders and large assortments, and very adapted to e-commerce orders fulfillment or store orders fulfillment.

Put-to-Light (or PTL) is a support technology for this type of process: LED modules light are attached to the shelves or to picking the cart, and lights on to direct the logistics operator on where to drop the goods.

Put-to-Light can be used in other breakdown processes, such as pick-to-cart with multiple orders, as well as reverse logistics (returns, …) and cross-dock.

The benefits of Put-to-Light

While put-to-lights systems have been used for a while in warehouses, they still remain used in the most modern warehouses. Here is why.

Service quality: increase customer satisfaction

Productivity: reduce your costs

Our process

Sorting: breaking down the orders

Initiate sorting

Sort to order

Drop and validate

Packing: from order to delivery

Ready to pack

Packing operation

End of order lifecycle

Once the order is finished, LED lights off, and the location is available for sorting again!

Our uncommon features

- Concurrency: manage several logistics operators working on the same sorting unit (shelve, cart), by using different light colors

- Efficiency: manage different pack levels with different EAN (ex: sort one pack of 6 in one single scan)

- Assign the right location size to the right order based on volumes. Overflow if the desired location size is full.

- Manage locations outside of put-to-light, for oversize items or to manage demand peaks

- Optimized location search algorithm: priority to orders close to completion, "fill the holes" for new orders

- Manage packing side with LED modules, including exceptions such as urgent orders and orders with multiple locations

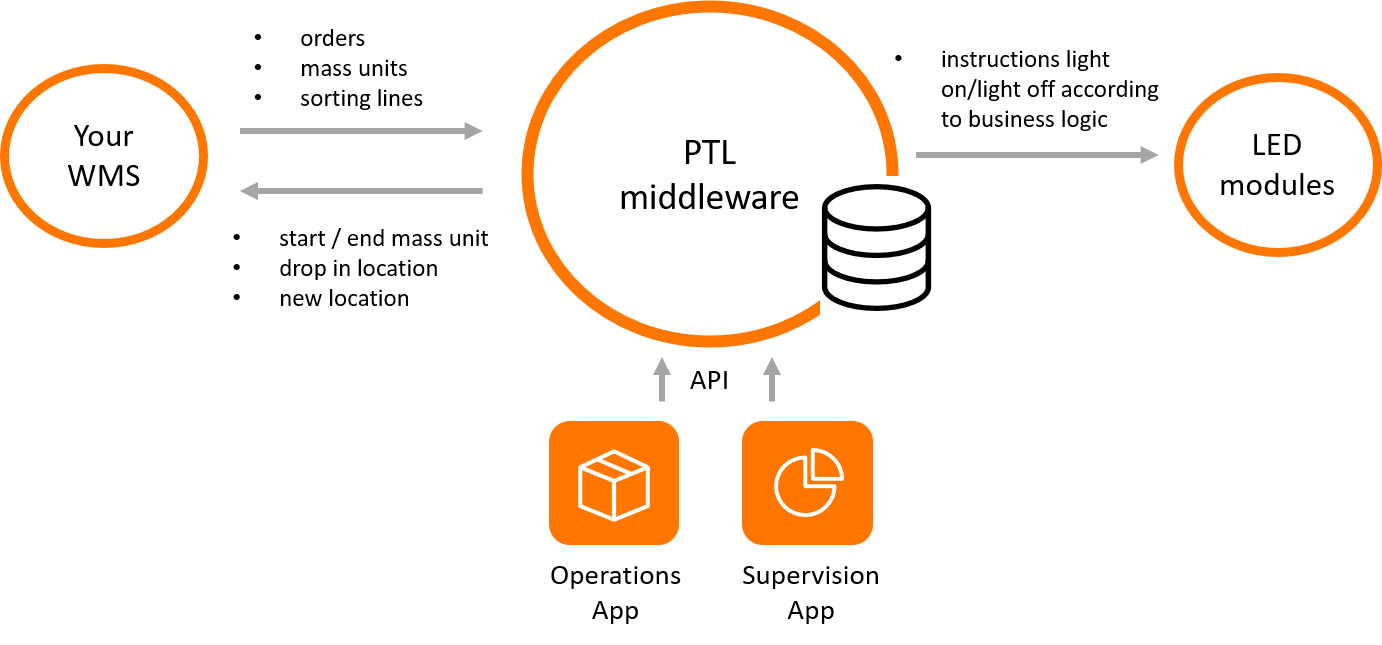

Put-to-Light Middleware